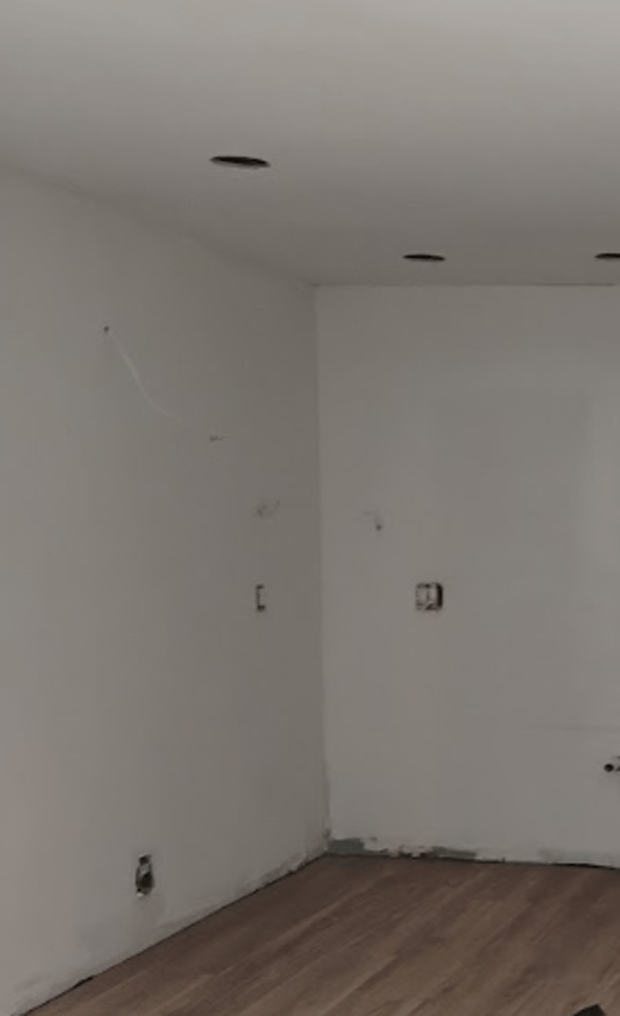

Skim coating is a popular technique employed in finishing to create a smooth surface that’s ideal for painting or wallpapering. This process involves applying a thin layer of joint compound over drywall, effectively concealing seams, blemishes, and minor imperfections. Skim coating is particularly valued for its ability to transform textured or inconsistently finished walls into a perfectly even surface.

Creates a flawless finish for painting or wallpaper application.

Benefits of Skim Coating

Conceals imperfections and repairs surface damage.

Improves the aesthetic appeal of both residential and commercial interiors.

Tools Needed for Skim Coating

- Joint compound

- Taping knife or putty knife

- Sandpaper or sanding block

- Mixing paddle and drill

- Roller (optional)

If necessary, patch any significant holes or cracks before commencing the skim coating process.

Steps to Skim Coat Drywall

Preparation

Begin by preparing the drywall. Clean the surface thoroughly to remove dust and debris.

Mixing the Joint Compound

Using a drill with a mixing paddle, thoroughly mix the joint compound to achieve a creamy consistency.

It should be smooth yet thick enough to adhere to the drywall surface without sagging.